Best Practices For Selecting Reliable Molded Pulp Suppliers

Selecting the appropriate suppliers is essential for companies looking to preserve sustainability, efficiency, and quality in today’s cutthroat market. When it comes to molded pulp packaging, selecting reliable suppliers can significantly impact product quality, cost-effectiveness, and environmental sustainability. This article explores the best practices businesses should consider when selecting molded pulp suppliers to ensure they meet their specific needs and standards.

Molded Pulp Packaging

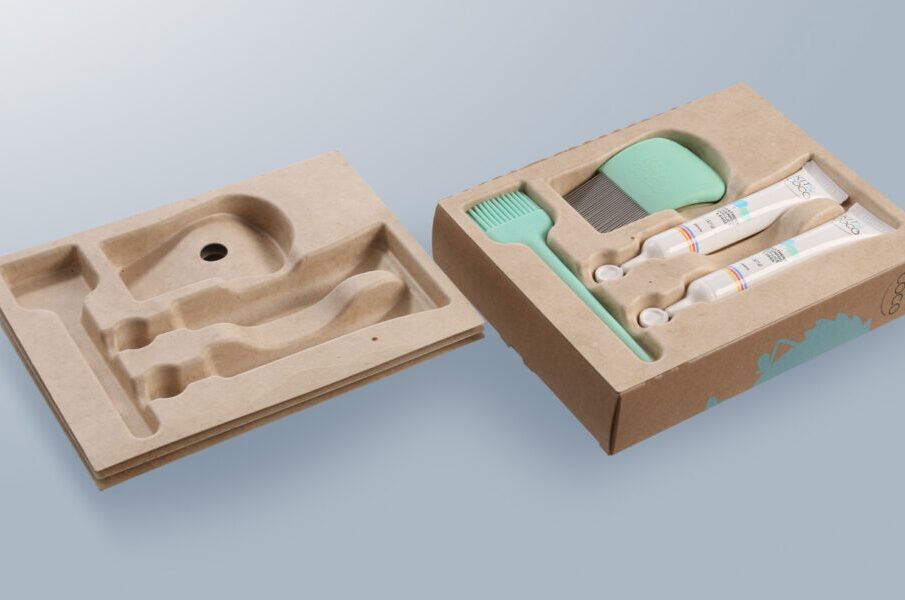

Before delving into selecting suppliers, it’s essential to understand what molded pulp packaging entails. Molded pulp, often made from recycled paper and cardboard materials, is a versatile and eco-friendly material used for packaging applications. It is valued for its protective properties, biodegradability, and ability to be molded into various shapes to fit specific product dimensions.

Importance Of Choosing The Right Supplier

The supplier you choose for molded pulp packaging can impact several aspects of your business:

- Product Quality: Superior molded pulp lowers the possibility of damage and returns by ensuring your products are sufficiently shielded during storage and transit.

- Cost Efficiency: A reliable supplier can offer competitive pricing without compromising on quality, helping to optimize your packaging costs.

- Sustainability: Molded pulp is inherently eco-friendly, but sourcing from suppliers committed to sustainable practices enhances your environmental credentials.

- Supply Chain Reliability: Dependable suppliers contribute to smoother operations, minimizing disruptions and ensuring timely deliveries.

Best Practices For Selection

When selecting molded pulp suppliers, consider the following best practices:

-

Define Your Requirements

Begin by clearly defining your packaging requirements. Consider factors such as product dimensions, fragility, storage conditions, and regulatory compliance. It would be easier for you to interact with possible providers and make sure they can fulfill your requirements if you are aware of these details.

-

Assess Supplier Experience And Expertise

Seek out vendors who have experience with molded pulp packaging. Experience indicates familiarity with industry standards, technological advancements, and best practices. Check if the supplier has served businesses similar to yours and inquire about their experience in handling specific packaging challenges.

-

Evaluate Manufacturing Capabilities

Visit or audit the supplier’s manufacturing facilities if possible. Assess their production capabilities, equipment quality, and adherence to quality control measures. A well-equipped facility with robust processes is more likely to deliver consistent and reliable products.

-

Quality Assurance And Certifications

Verify the supplier’s commitment to quality assurance. Ask about their quality control procedures, certifications (such as ISO standards), and compliance with regulatory requirements. Certifications validate adherence to industry standards and ensure consistent product quality.

-

Sustainability Practices

Assess the supplier’s sustainability initiatives and practices. Molded pulp is inherently sustainable, but suppliers may vary in their sourcing of raw materials, energy efficiency, waste management, and carbon footprint reduction efforts. Choose suppliers aligned with your organization’s sustainability goals and values.

-

Pricing And Cost Transparency

Obtain detailed pricing proposals from potential suppliers, including costs for tooling, production, and delivery. Transparent pricing structures help you evaluate cost-effectiveness and budget accordingly. Beware of excessively low prices that may compromise product quality or supplier reliability.

-

Supply Chain And Logistics Capabilities

Evaluate the supplier’s supply chain and logistics capabilities. Ensure they can handle your expected order volumes, provide reliable lead times, and accommodate fluctuations in demand. Clear communication and efficient logistics are critical for maintaining uninterrupted supply.

-

Customer Support And Communication

Assess the supplier’s responsiveness and willingness to provide ongoing support. Effective communication channels and proactive customer service contribute to a productive supplier relationship. Clarify expectations regarding order updates, issue resolution, and continuous improvement initiatives.

-

References And Reputation

To determine dependability and degree of satisfaction, ask for referrals from previous or present customers. Online reviews, industry reputation, and referrals can provide valuable insights into a supplier’s performance, customer service, and overall reliability.

-

Negotiate Terms And Contracts

After you’ve found a reliable provider, work out terms and conditions that meet your needs as a business. Ensure contracts cover pricing, delivery schedules, quality standards, warranties, and dispute resolution mechanisms. Clarity in contractual agreements minimizes potential misunderstandings and protects both parties’ interests.

Conclusion

Selecting reliable molded pulp suppliers involves careful consideration of various factors, from product quality and sustainability practices to supply chain reliability and pricing transparency. Businesses can create strong partnerships, navigate the supplier selection process with ease, and increase the sustainability and efficiency of their packaging operations by adhering to these best practices. Remember, choosing the right supplier is not just about cost—it’s about ensuring alignment with your business goals and delivering value throughout your supply chain.